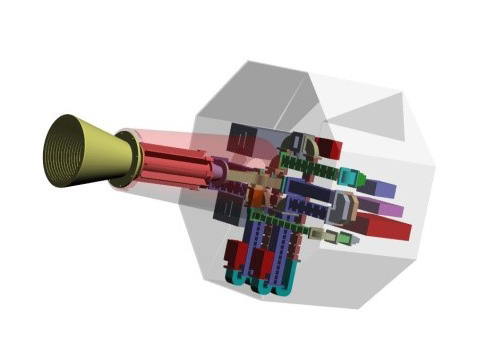

Radio frequency design

The strong experience of Sicilsat Communications in the development of Radio frequency is able to meet every needs as part of Satellite Communications and in general for all applications where the use of microwaves is required.

Our company is able to design and build any satellite communication system (mobile or fixed), subsystems (feed, sub-reflectors, etc.) for any frequency and power. We are also able to develop, according to the required needs, each RF component (guide filters, OMT, corrugated horn, sealing windows for power waveguides, etc.).

The most up-to-date SW applications (Mician µWave Wizard™ and other internal developed software based on modal matching) are used in the development activities, able to carry out all the simulations necessary to guarantee the achievement of the requirements. Furthermore, each device is subjected to careful testing, in order to validate and certify that the requirements are met.

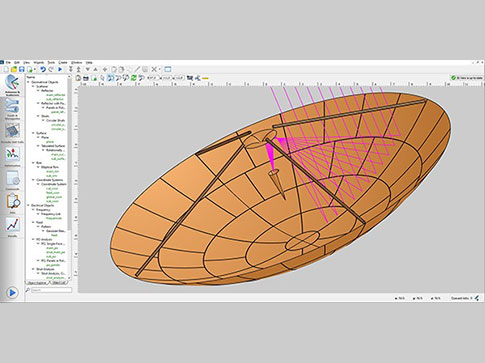

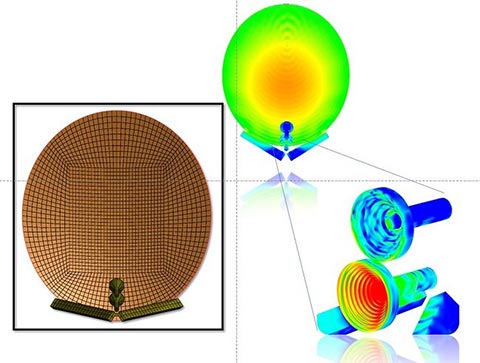

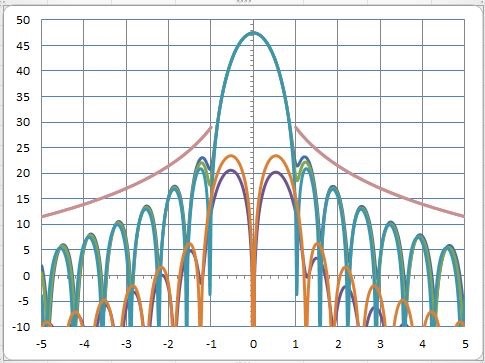

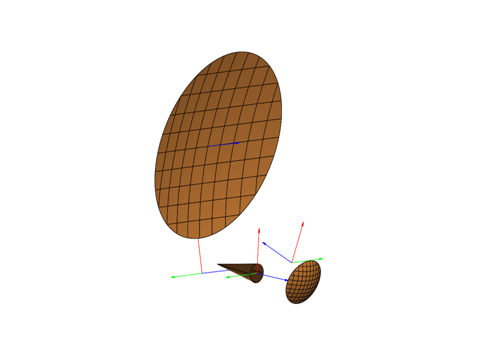

Antenna geometry design

Our company is able to design and, where required, supply any geometry of main reflectors and sub-reflectors to be used on satellite communication systems (mobile or fixed).

The Grasp and Champ Software from Ticra™ is used in the development activities. Simulated radiation patterns are always made available to customers.

If the realization of the reflector / sub-reflector is required, the company carries out all the tests to verify the compliance of the product with the mechanical project. Moreover, the availability of an adequate set-up, allows the verification of the conformity of the device with the radiation diagram simulated by means of the SW application.

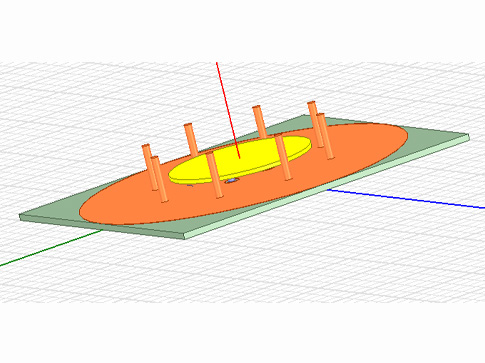

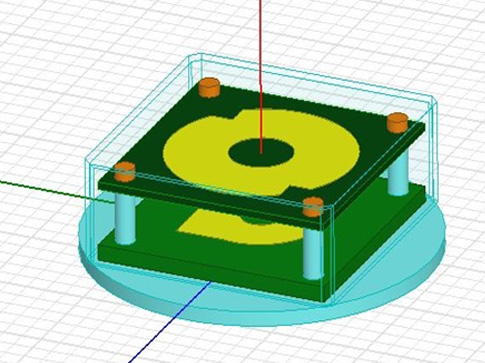

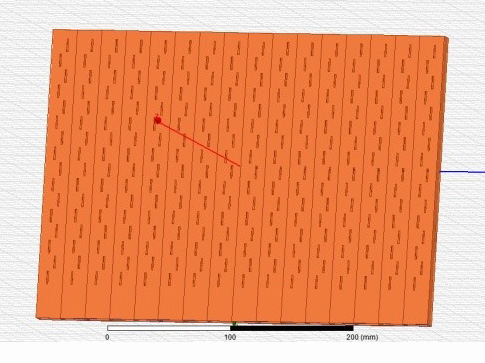

Microstrip or Planar Antenna Design

In addition to the conventional technology (Optical reflection), Sicilsat Communications is able to design and deliver antennas in Radiating or active elements, in microstrip or planar coaxial technologies.

For the development of the radiant structures in this state-of-the-art technology, our designers use Mician µWave Wizard™, as simulation software.

Using this development method we are able to create both passive and active antennas.

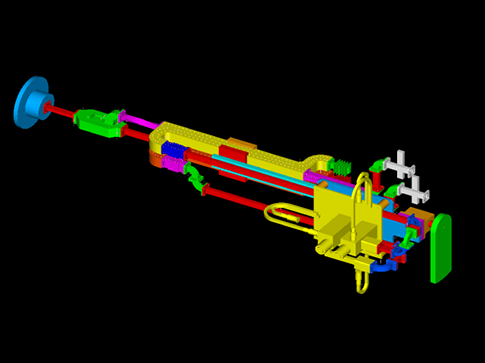

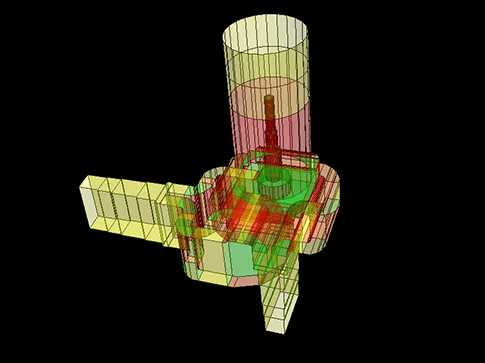

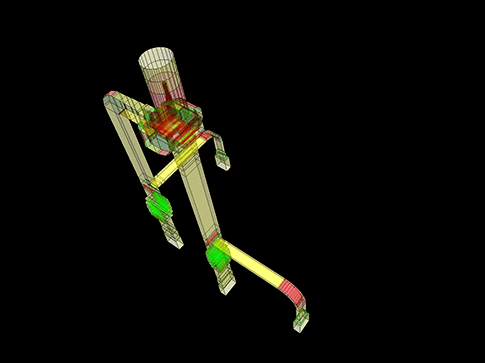

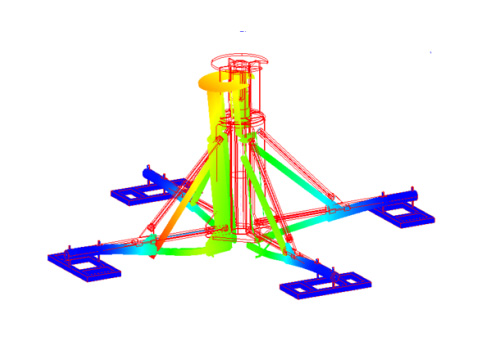

Mechanical Design

The mechanical design of each Sicilsat Communications device is carried out by the company’s staff thanks to powerful use of the CAD/CAM systems capable of analyzing complex mechanical structures.

In order to guarantee maximum precision in the execution of the mechanical development activity, particular care is given to the following project elements:

- Tolerance analysis

- Thermal analysis

- Resonance frequency analysis

- Stress Analysis of complex antenna structure and motorization

- Load wind and earthquake load analysis

- Ease of maintenance and operation

The project documentation created allows specialized workshops to safely create the mechanical parts and also allows the assembly of all parts.

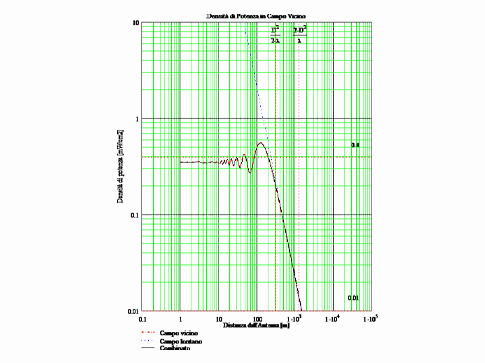

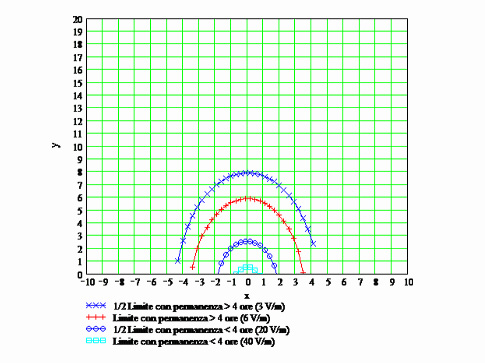

Safety and EMC Design Analysis

We are able to carry out accurate EMC safety analysis for any job site and customer. In the documentation presented, we evaluate all risks of danger due to radiation from the antennas and describe, for each type of construction site and type of installation, all the safety procedures to be adopted to minimize the risk.

The risk assessments are made on the basis of the European legislature in force.

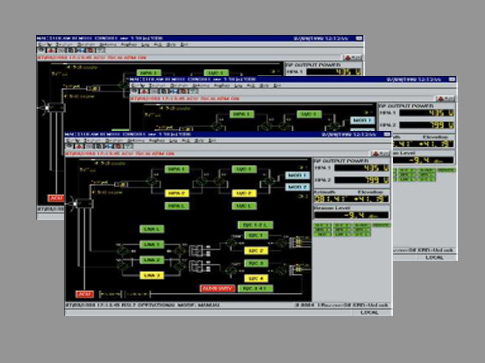

Monitor & Control

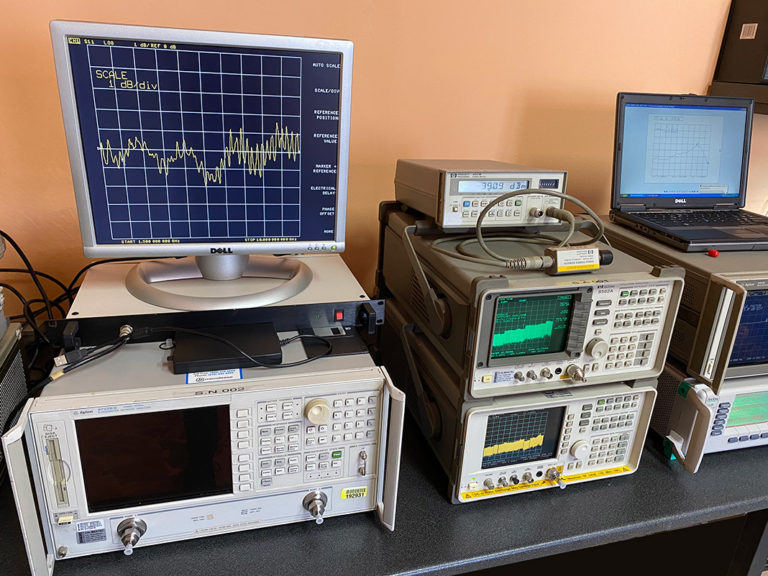

Accuracy in measurement

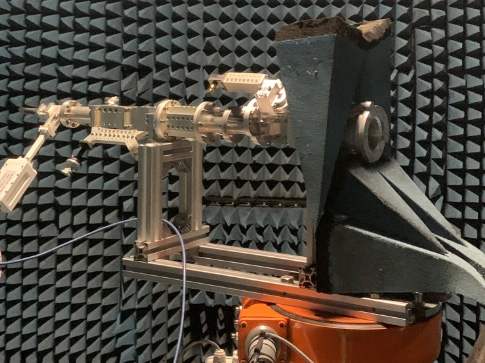

Sicilsat Communications is able to validate each developed device with the necessary accuracy. For this purpose, in addition to having a wide range of instrumentation to fully test the coaxial and waveguide components from 10 MHz to 50 GHz, it is able to use an equipped anechoic chamber and, where necessary, a “Radio tests set”, which uses a useful position on Etna at an altitude of 1800 m above sea level.

All our equipment is subjected to periodic verification and calibration.

The checks on our devices are carried out using specific test procedures, which detail the conditions and methods of the measurement and the values to be obtained to pass the tests. Therefore the company can provide its customers with detailed records for each apparatus under test.